FUJITSU TEN Develops World-leading Mass-saving Car Speakers

- Mass cut by around 30% from previously, with sound quality unchanged -

- 430 ton/year reduction in mass -

January. 13, 2015

FUJITSU TEN LIMITED

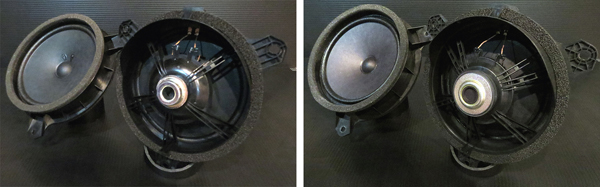

Newly developed mass-saving speakers (Left : uses neodymium magnets. Right : uses ferrite magnets)

FUJITSU TEN LIMITED (Head Office: Kobe City, Hyogo Prefecture, President and Representative Director: Akira Yamanaka) has developed world-leading(*) mass-saving car speakers that cut mass by 30% from previous levels while preserving sound quality. The newly developed speakers are the 16cm diameter size that most vehicles are standardly equipped with. We developed two types of speakers: one that uses neodymium magnets (135g - about 30% lighter than our previous products), and another that uses ferrite magnets (190g - about 35% lighter than our previous products). These speakers are already being employed by Japanese car manufacturers and we have begun sequenced delivery. With the number of speakers that are firmly ordered at the moment, it will be possible to reduce mass by around 430 tons/year compared with the same number of traditional-spec speakers.

Our thinking is to apply the newly developed technology in speakers of other sizes than 16cm and intensify our activities proposing them to car manufacturers in Japan and abroad, so as to have them carried by more vehicles and thereby contribute to mass saving and global environmental preservation.

The Newly Developed Products

| Type | Mass | Reduction from our previous products(*) |

|---|---|---|

| 16cm dia. car speaker using neodymium magnets | 135g | ▲ About 30% |

| 16cm dia. car speaker using ferrite magnets | 190g | ▲ About 35% |

Backdrop to the Development

At the same time as automobiles are spreading all over the world, global warming and air pollution by exhaust gas have become serious problems. In the automobile industry, development of vehicles that can run long distances on little fuel is proceeding apace, primarily through development of hybrid vehicles, electric vehicles and fuel cell cars. Efforts are also being made to render vehicles mass-saving in order to improve fuel efficiency. Lower mass for vehicle bodies and for parts of all kinds is being worked on, and the car speakers we have developed are one of such efforts.

The Issues

Speakers that use highly powerful neodymium magnets in their magnetic circuits began to be employed by car manufacturers around 1995, and enabled the mass to be brought down to 200g or so from the 600g or so up to that time. But it was difficult to achieve any more mass saving than that while preserving the sound quality, and development stagnated. Also, being made of scarce materials, neodymium magnets were costly and liable to soar further in price.

At the same time, the ferrite magnets that had been traditionally used were low in magnetic power compared to neodymium magnets, so that reducing their mass while preserving sound quality was viewed as problematic.

Newly Developed Technology Common to Neodymium and Ferrite Types

We reexamined the frame and the magnetic circuits, which together account for around 80% of the speaker's mass.

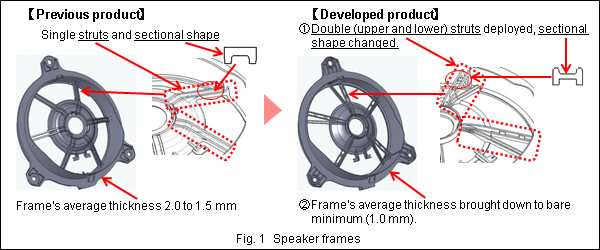

1) Development of mass-saving speaker frame (Fig. 1)

Issue : Simply making the frame thin to render it mass-saving would lower its strength, so that unwanted resonance would occur and the sound quality would degrade.

Main measure : Through optimization of the frame shape using strength analysis simulation techniques, we developed a "vibration distributing frame" that distributes vibration while achieving increased thinness.

①Assured strength, enhanced sound quality - double (upper and lower) struts are deployed, and their sectional shape is changed.

②Lower mass - frame's average thickness is brought down to a bare minimum (1.0 mm).

Note : This figure represents the type that uses neodymium magnets. Similar structure and measures are applied in the type that uses ferrite magnets.

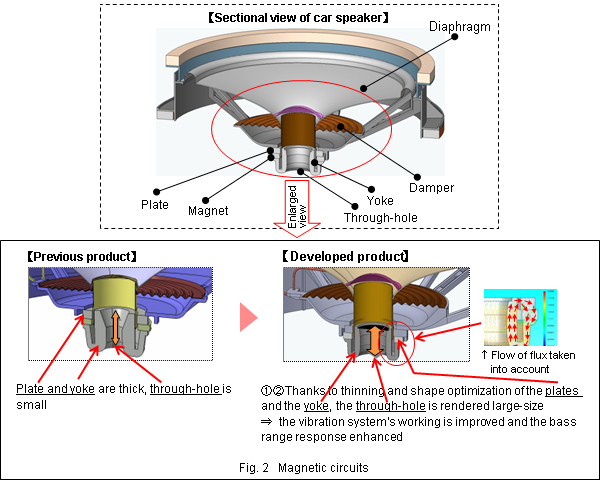

2)Development of mass-saving magnetic circuits (Fig. 2)

Issue : If the yoke were rendered thin, the magnetic flux density for driving the diaphragm would drop, with the result that the acoustic pressure would drop and also the sound quality would degrade.

Main measure : By achieving optimization of the magnetic circuit shape using magnetic circuit simulation techniques, and finding the shape that is able to minimize the volume while assuring the magnetic flux density, we succeeded in rendering thin the yoke. This enabled us to make the through-hole large-size, and thereby to ease the flow of the air and improve the vibration system, thus enhancing response in the bass range.

①Lower mass - by rendering thin the plates and yoke and optimizing their shapes

②Lower mass and enhanced sound quality (bass range response) - by rendering large-size the yoke's through-hole

Note : This figure represents the type that uses neodymium magnets. Similar structure and measures are applied in the type that uses ferrite magnets.

Notes

* As of January 2015. Data from Fujitsu Ten surveys.About FUJITSU TEN

FUJITSU TEN LIMITED, established in 1972 with investment from FUJITSU LIMITED and with additional investment from Toyota Motor Corporation and DENSO Corporation in 1973, is a leading manufacturer of automotive electronic equipment.

It is a globally-recognized manufacturer of car navigation and audio systems, ECU for engine and airbag control, millimeter wave radar, mobile communication equipment and so on. It is expanding its business globally by fulfilling orders for genuine products for Toyota and other automobile manufactures both domestically and overseas.

Consolidated sales totaled 303.3 billion yen for the fiscal year ending March 31, 2014.

For more information about the Group and its businesses, please visit website at http://www.fujitsu-ten.com/

FUJITSU TEN channel https://www.youtube.com/FUJITSUTENLIMITED

FUJITSU TEN facebook http://www.facebook.com/FUJITSUTENLIMITED

The contents of a press release are as of the publication. Later, they are apt to be changed without notice. Thank you for understanding in advance.